Globally, an increasing number of automobile manufacturers are aiming at reducing the overall weight of the vehicle in order to improve the fuel efficiency, optimize the part geometry cost, and consolidate the vehicle assembly operations. Custom-molded solutions enable vehicle manufacturers to replace iron, bronze, and steel components with plastic injection molded parts.

Consequently, the custom plastic injection molding market is expected to witness a significant growth in the automotive industry owing to its huge demand in this segment. In fact, a market report shares that the global market for plastic injection molding products is expected to reach USD 252 billion in this year.

This article shares information on custom plastic injection molding and its significance in the automotive industry.

What Is Custom Plastic Injection Molding?

The automotive industry is going through significant changes in the design and manufacturing domain. Injection molded plastic is being used to manufacture several complex automobile components and assembled parts owing to their lightweight, durability, enhanced performance, and high-tolerance as rigid as 0.001 inches.

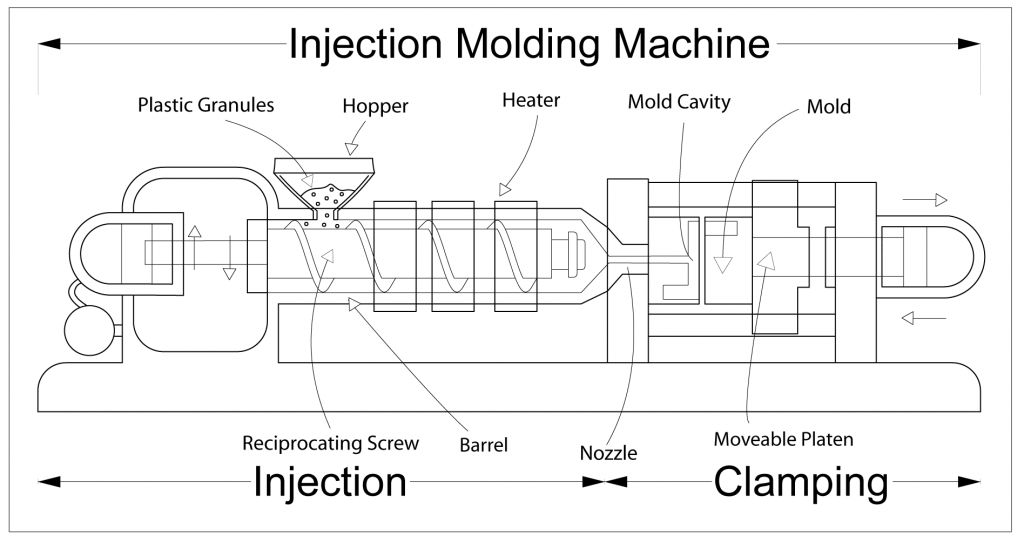

Custom plastic injection molding involves the application of the latest molding process technology, the analytical tools, and the plastic component design to manufacture complex automotive parts with precision. Depending on the automobile firms’ requirements, the designing and the engineering team develop specialized designs and identify the most suitable molding process and material to be used for making the components.

Every manufactured part demands a specific molding process. Mentioned below are the types of molding processes that are most commonly used to manufacture everything from storage containers to automobile parts.

1. Blow Molding

This process is best suited for manufacturing one-piece hollow objects, namely plastic bottles and containers.

2. Compression Molding

Numerous parts of the car, namely the seat mesh insulation, the gear stick knobs, and more are manufactured using the hydraulic press.

The compression molding process is used for manufacturing large and intricate automobile parts with the help of high-strength materials such as thermosetting resins, fiberglass, and reinforced plastic. The material (plastic or metal) is placed into heated molds and pressure is applied to attain the desired geometry and shape.

3. Extrusion Molding

The extrusion molding process extrudes the molten plastic into a die to produce hollow parts, namely tubings, pipes, and straws.

4. Rotational Molding

The rotational molding process uses the centrifugal force to produce large, hollow, and one-piece units such as containers and tanks.

5. Injection Molding

This process is the most versatile of all the other techniques mentioned above. It is highly suitable for projects that demand high precision and volume within a short period of time. A variety of presses and materials can be used to manufacture customized automobile parts, increasing the flexibility for designers and engineers.

Thus, the customized plastic injection molding process enables automobile manufacturers to employ plastic-reinforced parts, reducing the weight of the vehicles without compromising on the quality and the timelines.

Custom Plastic Injection Molding versus Die Casting

Custom plastic injection molding and die casting are used by numerous manufacturers around the globe to produce various components of machines and automobiles. Yet, both these processes have certain advantages and limitations that the designers and the engineers of manufacturing firms must be aware of.

Advantages and Limitations of Die Casting

Die casting is a process by which metals are melted and forced into steel molds using intense force. The necessary pressure is maintained till the molten metal cools and solidifies, following which the casting is taken out of the die.

Advantages

- This process is suitable for producing high-durability and dimensionally-stable metal parts that can withstand extreme temperatures.

- Die-cast parts can be manufactured at a high speed while maintaining close tolerances.

Limitations

- This process is not suitable for manufacturing components with highly complex designs, namely medical and automobile parts.

- Several thermal factors (such as phase transition in metals and thermal fatigue) impact the service life of the manufactured components and cause recrystallization and cracks in the final product. This factor isn’t much of a concern in the plastic injection molding process.

- Though the die parts are stronger in comparison to the plastic injection moldings, they are extremely heavy, making it unbefitting for automobile manufacturers who are looking to reduce the overall weight of the vehicles.

Advantages and Limitations of Customized Plastic Injection Molding

Here are a few pros and cons of the customized plastic injection molding process that firms must consider before using it for producing automobile parts.

Advantages

- The high accuracy, the flexibility, and the speed of the process enable manufacturers to fabricate any type of plastic component within a short period, improving the efficiency of the firm and reducing the operational costs.

- During the production, fillers can be added to enhance the strength of the final products. Consequently, this process is ideal for industries that demand high-strength machine components.

- The plastic parts that come out of the molds have a smooth and finished appearance. As a result, this process evades the need for the final product-finishing step, significantly reducing the labor costs.

- Multiple raw materials can be processed at the same time in the plastic injection molding machines, giving designers the flexibility and freedom to design without worrying about the operational hurdles.

Limitations

- Though the overall cost of production is minimal, the initial equipment cost and the customized molding production cost is high. However, once the mold is created the large-volume and high-speed production reduces the cost of the final product.

- The mold designs must be carefully created by engineers before the production begins, causing a possible delay in the manufacturing process. Designing takes anywhere between 8 to 12 weeks, causing longer lead time.

- It is tough to make modifications in the final product. Consequently, it is critical for manufacturers to go ahead with producing the molds only when they are completely sure that the dimensions and features are accurate.

Applications of Custom Plastic Injection Molding in the Automobile Industry

The plastic injection molding is one of the most widely used manufacturing processes across various industries. However, it is being increasingly preferred in the automotive industry owing to its ability to create customized, good-quality, and durable interior and exterior trim components, electronic sub-assemblies, and under-hood applications at a high speed.

Vehicle components, namely shifter knobs and assemblies, acrylic lens, instrument panel components, interior bezels, door handles, DVD housing, backlighting controls and buttons, and insert molded spacer blocks are manufactured using the custom plastic injection molding process. Depending on their applications, different types of plastics and engineered and commodity resins such as acrylonitrile butadiene styrene (ABS), acetal, and polypropylene are used to manufacture the automotive parts.

The Road Ahead: Custom Plastic Injection Molding Is the Key to Future of Lightweighting in Automotives

Custom plastic injection molding enables automobile manufacturers to offer ergonomic comfort while maintaining the fuel efficiency of the vehicles. For instance, a hydraulic liftgate manufactured using rigid and elastomeric thermoplastic polyolefins (TPO) is around 30 percent lighter than steel, reducing the fuel costs by ten percent.

The weight of a vehicle considerably impacts its fuel economy. Owing to the rising fuel prices, the increased carbon emissions, and the new government regulations, fuel efficiency will continue to be one of the crucial decision-making factors when purchasing a new car, a truck, or any other motor vehicle.

As a result, the automobile industry is aiming at improving the fuel efficiency of their vehicles by lightweighting the components and the assemblies used and downsizing the engines. By using recyclable plastic components manufacturers can also make their vehicles sustainable in the long term.

The constant improvement in the vehicle design and the vehicle weight reduction will drive the future of the automobile industry. Consequently, custom plastic injection molding has a huge role to play in the automotive domain, improving the fuel efficiency and aesthetics of vehicles.